Lead partner: DAF Trucks

Objectives:

- Engine optimisation;

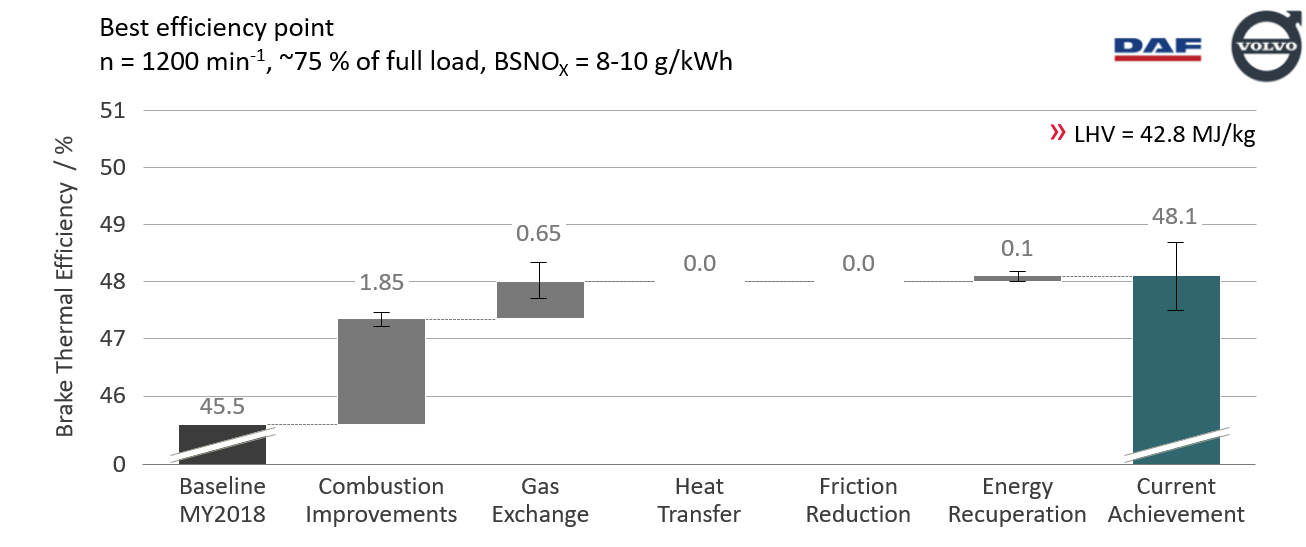

- target 50% efficiency in best point (mixture of demonstration of contribution of systems in test cell and simulation of complete engine) by enabling technologies;

- increased peak firing pressure capability of the engine allowing faster heat-release or higher compression ratio;

- higher turbine power due to more heat available for turbine (less heat to coolant) and higher turbocharger efficiencies (to be used for more diluted and more efficient combustion with low heat rejection to coolant and/or contribution of scavenging loop to net power or turbo compounding).

- target 50% efficiency in best point (mixture of demonstration of contribution of systems in test cell and simulation of complete engine) by enabling technologies;

- Engine robustness testing for advanced bio-fuels; reference fuel will be HVO (from bio mass); depending on the outcome of the horizontal work package blends with other bio fuels can be tested in the engine test cell;

- Vehicle optimisation 10% energy saving (based on MY 2018 reference vehicle) by improved ICE and improvements in the vehicles as improved aero dynamics and reduced rolling resistance and optimised vehicle functions (energy management of the vehicle); to be demonstrated in VECTO long-haul cycle.