To reduce GHG emissions and contribute to the project´s objectives, IRIZAR has proposed to develop a Hybrid vehicle with State of the Art (SotA) Internal Combustion Engine (ICE) fueled with Hydrotreated Vegetable Oil (HVO), incorporating advanced Hybrid Control Module (HCM) and smart Heating, Ventilation and Air Conditioning (HVAC) system. The proposed development will aim to achieve a 12% energy savings when compared to the i6s 2018 reference vehicle, which directly brings 12% of CO2 reduction. All these developments, findings and results will contribute to definition of the inputs-outputs for VECTO adaptations.

This powertrain is capable of working in different driving modes, from pure electric drive with ICE off, to an efficiently optimum torque split between ICE and eMotor in Hybrid drive.

The advanced motor is HVO compatible.

The objective of the implemented energy management strategy is to maintain the Sate of Charge (SOC) of the High Voltage (HV) battery stable at a given value. This strategy facilitates the integration of the route-dependent advanced algorithm under development as part of this project.

The newly developed HCM algorithm is responsible for selecting the most suitable driving operation mode to be active at each point in time. The HCM has special relevance in the efficiency of the powertrain, as it has the overview of every component and energy flow in the vehicle. Specific controls have been developed for each electrified auxiliary system, with the aim of making them work at their optimum operating point.

Connected strategies

The integration of the new energy management system and HCM algorithm in the vehicle enables efficient eMotor and engine loadings as well as maximization of kinematic energy recovery based on vehicle data. However, none of these systems consider off-board data to optimize their strategies. It is known that the vehicle environment has a considerable impact on its performance. Therefore, an energy strategy based on cartographic information is being developed to further improve the energy savings. Note that activation of this route-specific energy management optimization system requires the HCM algorithm on automatic mode.

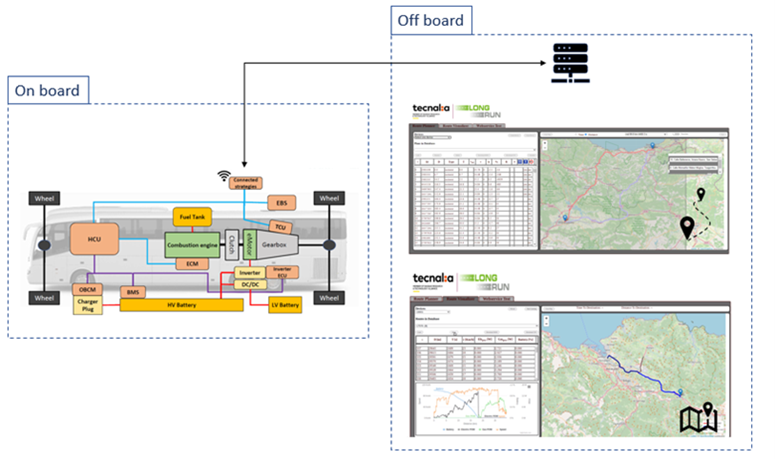

This system consists of two subsystems: an off-board server and an on-board subsystem, as presented in Figure 1. The off-board server allows route planning based on multiple metrics optimization. It also provides a fleet tracking service which logs and visually provides real-time vehicle data. The on-board system is responsible for the communication with the server and the calculation of the parameters to optimize the energy strategy for the route ahead. The system is depicted in the figure below.

Figure 1 – LONGRUN server and vehicle communication