Innovative combustion and ignition system – CFD and SCE activities performed by IFPEN together with FPT. The SwumbleTM concept for high-efficiency SI NG engines has been applied (patented).

Natural gas engines for heavy duty and medium duty applications presently are mostly spark ignited (SI) engines converted from parent diesel engine. These spark ignited engines are either operated on lean or stoichiometric air/fuel mixture. Lean burn engines have a 2-3% higher efficiency compared to stoichiometric engines, however a de-NOx aftertreatment technology is key requirement for Euro VI emission compliance. Stoichiometric SI gas engines can be operated with a 3-way catalyst, but suffer from a lower thermal efficiency and high exhaust gas temperatures. High level of turbulence produced by dedicated in-cylinder fluid motion is a key enabler for combustion strategies which lead to a 10% higher efficiency than conventional stoichiometric gas engines.

The specific objective of FPT during LONGRUN in respect of employing an innovative combustion and ignition system is to:

- Assess the specific advantages of a new combustion concept, with a target of thermal efficiency up to 50%;

- Demonstrate a minimum reduction of 30% gaseous emissions (NOx, CO, NMHC and CH4) and PN compared to Euro VI limits at test bench on WHTC with bio-methane. Target for NOx is 0.1g/kWh;

- Demonstrate effective emissions levels with bio-methane on a demonstrator vehicle running in real driving conditions with CF=1;

- Demonstrate 10% fuel efficiency compared to state-of-the-art 2018 stoichiometric natural gas vehicles in real driving conditions, complementing vehicle results with energy recovery systems results from test bench.

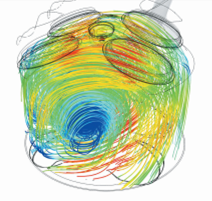

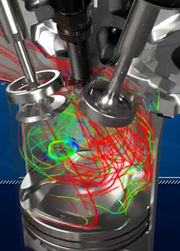

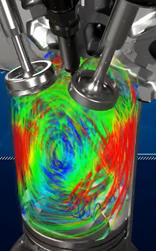

The objectives of FPT will be reached – among others -through an advanced combustion system, based on the SwumbleTM concept developed by IFPEN. The concept will be developed to increase the turbulence level and to allow the use of a Miller strategy with a pent-roof geometry. The Miller strategy allows an increase of the expansion ratio (and so of the engine efficiency) while maintaining a low compression ratio, while the high level of turbulence leads to a very fast combustion and both contribute to increase the engine’s thermal efficiency. CFD simulations will drive the design of the best SwumbleTM configuration and the effective performance will be tested on a single-cylinder engine. The engine will be then complemented with a pre-chamber spark plug, to guarantee the correct ignition of the mixture and an increase of the combustion speed even in presence of very high quantity of EGR, necessary to increase the engine’s efficiency.

Combustion system of natural gas engine with the SwumbleTM concept:

During the LONGRUN project, a new configuration of the combustion chamber for the C13 engine was designed and optimized by CFD calculations to increase TKE levels in the cylinder at TDC. The starting point was a tumble-based system of combustion, then a swirl component was added, thus reaching the “Swumble” configuration.

A paper will be presented by IFPEN at the 2024 MTZ Conference “Heavy-Duty, On- and Off-Highway Engines”

Design activities were performed to adapt IFPEN’s SCE to reference case of LONGRUN (testing with FPT’s C13 production engine).

Figure: IFPEN’s High Efficiency Gasoline Engine for future hybrid vehicles (Source: https://www.youtube.com/watch?v=SyS51zrP0B4)

The advantages of the SwumbleTM fluid motion technologies are:

- Reduction of the real-world fuel consumption

- Reduction of the emitted particulate mass and number: Very low particulate level due to the improved interaction between air motion and injection

- Higher flexibility for injection phasing optimization

- Improvement of mixture homogenization

Background

The work of FPT on the C13 engine (low pressure, spark ignited natural gas engine) was already started during the HDGAS project during which an Natural Gas HD engine employed direct injection of fuel and a Corona ignition system[1] for the first time. Moreover, the engine was equipped with a combustion system specifically designed for a spark-ignition engine, not just an adaptation of existing diesel designs.

[1] A corona discharge spark ignition is a method which can produce voltages as high as 100 kV which can ignite very lean air-fuel mixtures.