The target of Volvo’s work in LONGRUN was to achieve 50% thermal brake engine efficiency and 49,2 % was achieved on the WP3 LONGRUN engine.

In WP3 a new combustion engine concept has been developed. Here below the engine concept test is described, and information is given on engine performance and initial tests EATS on test bed.

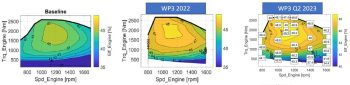

The best engine efficiency is located between 1000 and 1200 rpm. This is an effect of the developed turbo system. The compressor wheel size and trim largely determines at which engine speed range the engine will have its highest efficiency. A smaller compressor size tends to shift the region of highest engine efficiency to lower engine speeds, while a larger does the opposite. On the other hand, the turbine nozzle size typically determines how much EGR drive that can be obtained. Thus, in order to have an adequate level of EGR drive, at low engine speed, a sufficiently small turbine nozzle is needed. In contrast, a too small turbine nozzle leads to exceeding the turbocharger speed limit at higher engine speed and engine power. Thefore an integrated EGR pump enable good control over EGR rates and by that controling the engine out NOx emssions, without compresmise in optimising the turbosystem.

The best fuel efficiency at cruise vehicle speed (80-100kW) is obtained at approximately 1000rpm. However, this efficiency will be further optimized and evaluated when running the combustion engine in a hybrid set-up supporting the combustion engine with electric power and utilize the new energy management control strategies.

Engine efficiency is presented below, compared with the baseline engine.

The fuel used was B7, later it was substituted by HVO. Thanks to improved aftertreatment system performance savings, 0,5—1% improved thermal brake efficiency compared to earlier tests with other fuels was possible.